We work hand in hand with our clients to develop and evolve products over time

Research, develop and grow with us

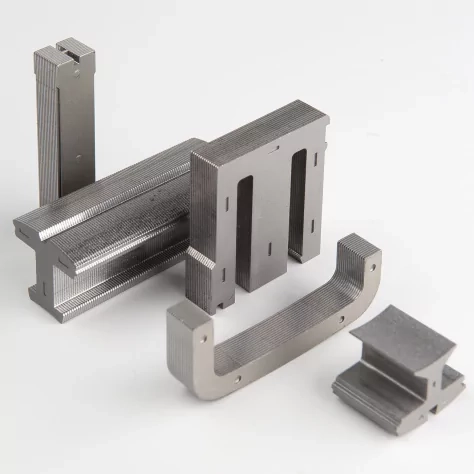

Stamping of electrical steels

We have been involved in the stamping of electrical steels since 1970.

Today we use high-speed presses with a modern control system and an impact force of up to 2,500 kN.

Our competences include:

- Rotor and stator stacks (non-rotated, straight or slanted slots, stacks made using compensation)

- Loose laminations

- Tool design and manufacturing

- Process development in line with automotive industry standards

- CAQ system (statistical computer-aided quality assurance)

- Automotive industry

- Ventilation systems

- Power tools

- Servomotors

- Household appliances

- High-speed presses with a modern control system and an impact force of up to 2,500 kN

- Stamping and packaging of electrical steel with a thickness of 0.20 mm to 0.50 mm

We can offer customers:

- Process development in accordance with automotive industry standards

- Construction and production of prototype tools, where samples are produced with serial parameters and the same technological procedure

- Construction and mass production of multi-row tools for stamping and packaging of electrical steel with a thickness up to 0.2 mm

- Highly productive tools equipped with control systems and systems for monitoring the tool stamping and protection process

Send inquiry about this product

We offer innovative development solutions

tailored to your preferences.