We work hand in hand with our clients to develop and evolve products over time

Research, develop and grow with us

Product Group

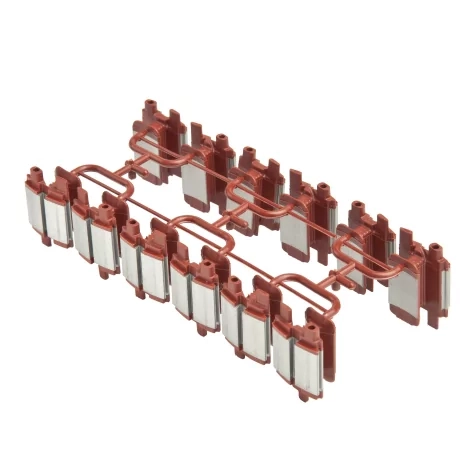

Overmoulding plastic insulation

This technology is an extension of our technology of stamping and packaging blades.

Our competences include:

· Overmoulding plastic insulation of rotor or stator stacks with straight or slanted poles and with or without compensation

· Thin-wall insulation

· Sigmasoft software for simulations

· In-house tool design and manufacturing

· 100% insulation quality testing

· Linked stamping and injection moulding technologies

- This technology is used for products in the automotive,

- HVAC and

- garden power tool industries.

- EC motors are used in all three areas.

The combination of stamping and overmoulding is our key competence, and a competitive advantage for our customers:

• Overmoulding insulation of stator stacks with straight or slanted poles and with or without compensation (PA, PBT, PET etc.)

• Sigmasoft injection moulding simulation

• This technology also enables high-quality and reliable insulation for high-voltage applications

• Excellent thermal conductivity, with greater design freedom for high voltage and media resistance

• Two different heights of overmoulded stack – one tool

• Tools are designed and produced in-house

Advantages of overmoulding technology compared to standard paper insulation:

· Only one tool for complete rotor or stator insulation (between the poles as well as top and bottom)

· Improved thermal conductivity

· Simplified motor winding

· Cost efficiency

Send inquiry about this product

We offer innovative development solutions

tailored to your preferences.