We work hand in hand with our clients to develop and evolve products over time

Research, develop and grow with us

Tool production

Own tool development and construction on the basis of many years of experience.

KEY ADVANTAGES

- Own tool development and construction on the basis of many years of experience.

- Knowledge of the most state-of-the-art technological processes of using tools and control and quality monitoring systems.

- Use and knowledge of stamping and injection moulding technologies.

- Highly productive tools equipped with control systems and systems for monitoring in accordance with the Industry 4.0 guidelines.

- Reliability and flexibility and customer support in the realisation of products.

- Vertically integrated process from product development to serial production.

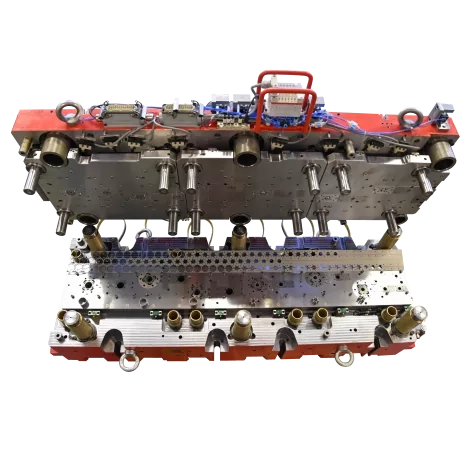

Cutting/packaging tools for stamping of electrical steels

- Production of prototype tools, where samples are produced with serial parameters and the same technological procedure.

- Mass production of multi-row tools for stamping and packaging of electrical steel with a thickness up to 0.2 mm.

- Highly productive tools equipped with control systems and systems for monitoring the tool stamping and protection process.

- Tools allow the production of indexed products with the function of switching cutting elements.

- Cutting elements are produced from sintered steel or hard metal with the use of coating procedures.

- Long lifetime of tools (more than 150 million cuts).

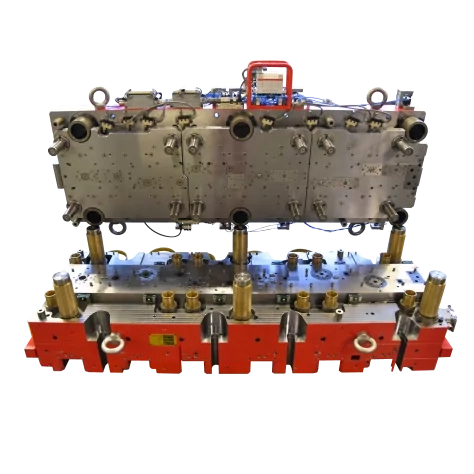

Tools for injection moulding of thermosetting materials

- Production of prototype tools, where samples are produced with serial parameters.

- Production of serial multi-cavity tools with sizes up to 6 tonnes.

- Development of tools and implementation of simulations of the entire injection moulding process, including the thermal analysis of tools.

- Highly productive tools equipped with control systems and systems for monitoring the injection moulding process.

- Production of vital components for tools with an accuracy > 10µm.

- Using high-quality tool steels and coating procedures.

- Carrying out measurements of the product with 3D scanning and CMM method, and optimising the product and process.

- Long lifetime of tools (more than 1 million injections).

Tools for injection moulding of metal elements with thermoplastic materials

- Production of prototype tools, where samples are produced with serial parameters.

- Production of serial multi-cavity tools with automatic process of inserting metal parts.

- Development of tools and implementation of simulations of the entire injection moulding process, including the thermal analysis of tools.

- Highly productive tools equipped with control systems and systems for monitoring the injection moulding process.

- Production of vital components for tools with an accuracy > 10µm.

- Using high-quality tool steels and coating procedures.

- Carrying out measurements of the product with 3D scanning and CMM method, and optimising the product and process.

- Long lifetime of tools (more than 1 million injections).

Die casting tools

- Die casting tools with sizes up to 6 tonnes.

- Using high-quality tool steels and coating procedures.

- Development of tools and implementation of simulations of the entire casting production process.

- Carrying out measurements of the product with 3D scanning and CMM method, and optimising the product and process.

Send inquiry about this product

We offer innovative development solutions

tailored to your preferences.