We work hand in hand with our clients to develop and evolve products over time

Research, develop and grow with us

BMC at Domel — Thirty Years of Innovation in Duroplast Technology

The Beginning: A Story of Bold Decisions

Back in 1992, Domel was searching for a way to reduce the cost of motor housings for vacuum units. At the time, aluminium was the industry standard — strong, familiar, and reliable, but also expensive, energy-intensive, and dependent on additional machining. Modernizing the foundry would have required heavy investment.

Our engineering team began exploring alternatives and soon turned its attention to technical plastics. Thermoplasts, however, were too costly to be a feasible solution.

The breakthrough came from an unexpected direction. While preparing several prototype rotors with double insulation for customer’s angle grinder project, Domel learned that customer achieved double insulation not with purchased sleeves — the approach Domel used — but by injection-moulding the rotor stack and shaft using a duroplast material called BMC (Bulk Moulding Compound).

The cost? Only one Deutsche Mark per kilogram.

The potential? Transformational.

This discovery set a new vision in motion. Domel connected with a manufacturer of injection-moulding machines, who referred us to a producer of BMC compounds. With their guidance, we modified an existing aluminium die-casting tool and began experimenting. Step by step, we learned how to process duroplast materials and optimize the technology.

What began as an experiment soon became one of Domel’s most important production competencies.

From First Trials to Fully Automated Production

The early trials took place in Železniki, where serial production was later established. As demand grew, the BMC department moved to a new manufacturing facility in Škofja Loka at the end of 2016 — a modern, purpose-built plant that today houses our BMC injection-moulding operations.

Over the course of three decades, the technology has evolved dramatically. Domel now operates 23 injection-moulding machines with clamping forces ranging from 1,200 to 4,510 kN, enabling us to produce everything from small insulation components to large electric-motor housings.

One of the most significant advancements is a high degree of automation. Several machines operate within integrated production cells that include:

- two injection-moulding machines,

- advanced product cleaning using dry ice cleaning or ionized air,

- automated end-of-line quality inspection.

The result is higher productivity, fewer defects, and exceptional process repeatability.

For the most demanding products, we rely on dry ice cleaning, which ensures clean, smooth surfaces without the use of chemicals.

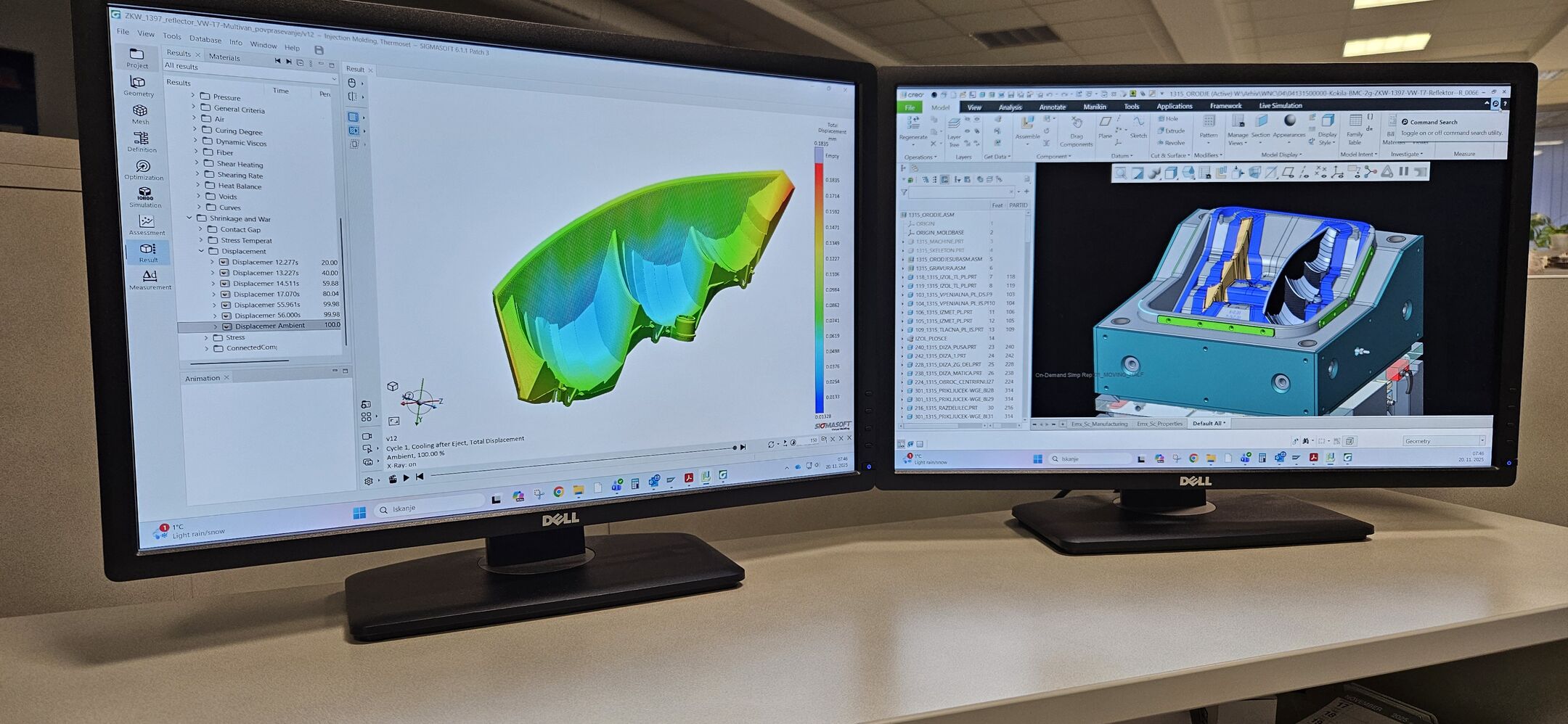

Digital Development: Precision Through Simulation

With Sigmasoft software, we analyse material flow and behaviour inside the tool, enabling us to identify and eliminate potential issues during the design phase. This significantly reduces tool modifications after first testing, shortens development cycles, and accelerates the path from concept to serial production.

Because Domel combines development, simulation, toolmaking, and production under one roof, we can support customers with rapid response times, reduced lead times, and full control over quality.

Patented Solutions and In-House Toolmaking

A key milestone in our BMC journey was the development and patenting of a process for inserting metal reinforcements into duroplast components. Created in collaboration with a customer, this solution has become one of Domel’s competitive advantages.

It allows us to mould metal parts, contacts, and switches directly into BMC components — opening new opportunities for technically advanced applications.

Our in-house toolshop enables fast optimization, seamless communication between departments, and full technical support throughout the product’s lifecycle. One partner, one process — from idea to final product.

Reliability Built on Precision

Because BMC is sensitive to heat and humidity, Domel maintains a climate-controlled warehouse with continuously monitored conditions. This ensures consistent material quality, longer shelf life, and stable production processes.

Three decades of experience have given us a deep, practical understanding of how materials behave and how they influence mechanical performance. Thanks to this know-how, we can produce technically complex, durable, and visually refined BMC parts — a true alternative to aluminium in many industries.

People First: The Heart of Production

Behind every technological milestone stands a team.

At the Trata1 plant, nearly 250 experts work together — technologists, designers, quality specialists, maintenance staff, logisticians, project managers, and production operators.

Knowledge flows continuously between departments: from design to technology development, toolmaking, and production. As one production manager puts it:

“We are a team that thrives on challenges. Every optimization we make becomes shared knowledge — and makes us even better.”

We also collaborate with universities and research institutions because we believe that innovation grows from the exchange between industry and science.

Products We Are Proud Of

Some of the products that best reflect our journey include:

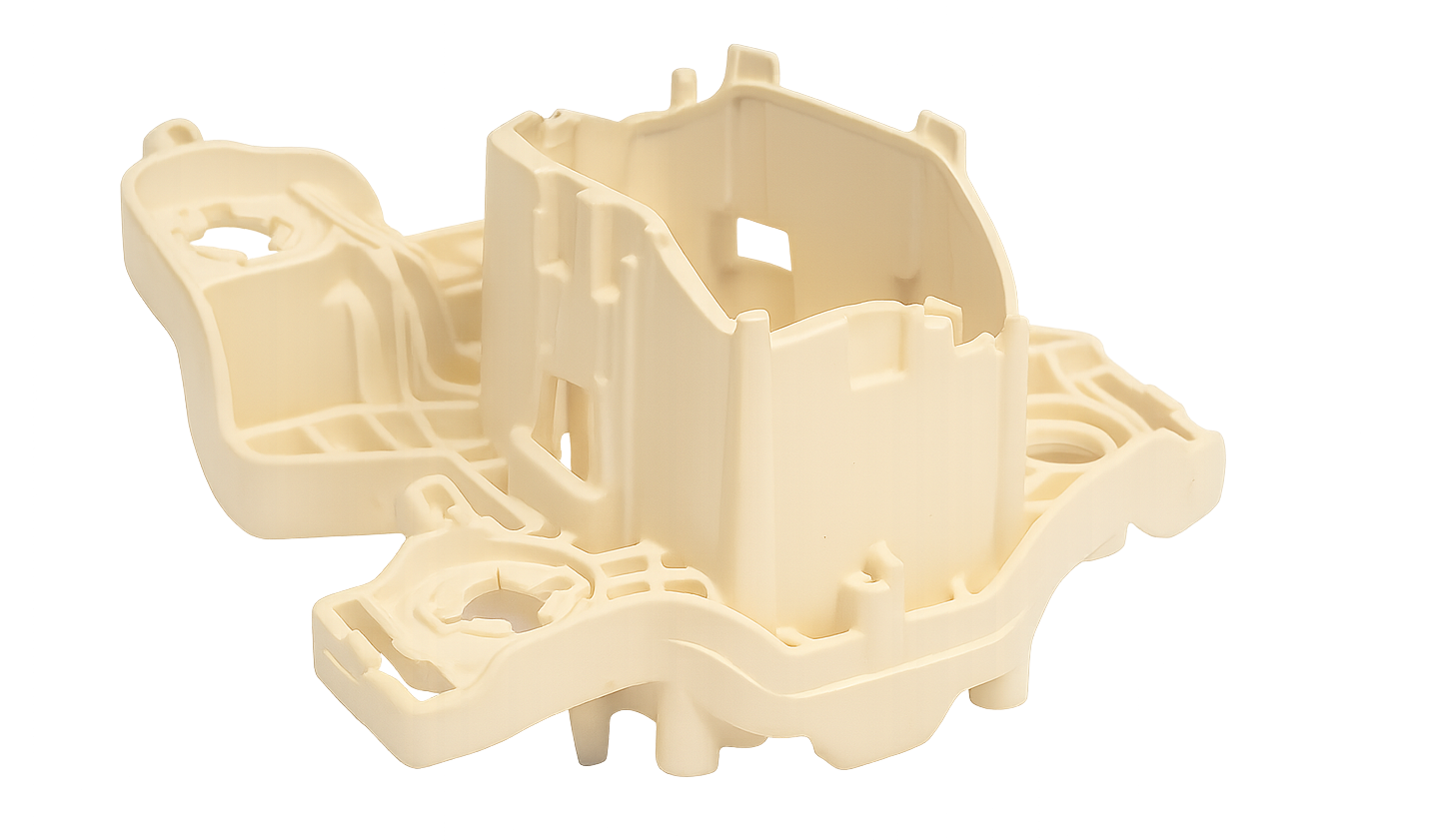

- air-flow controller housings,

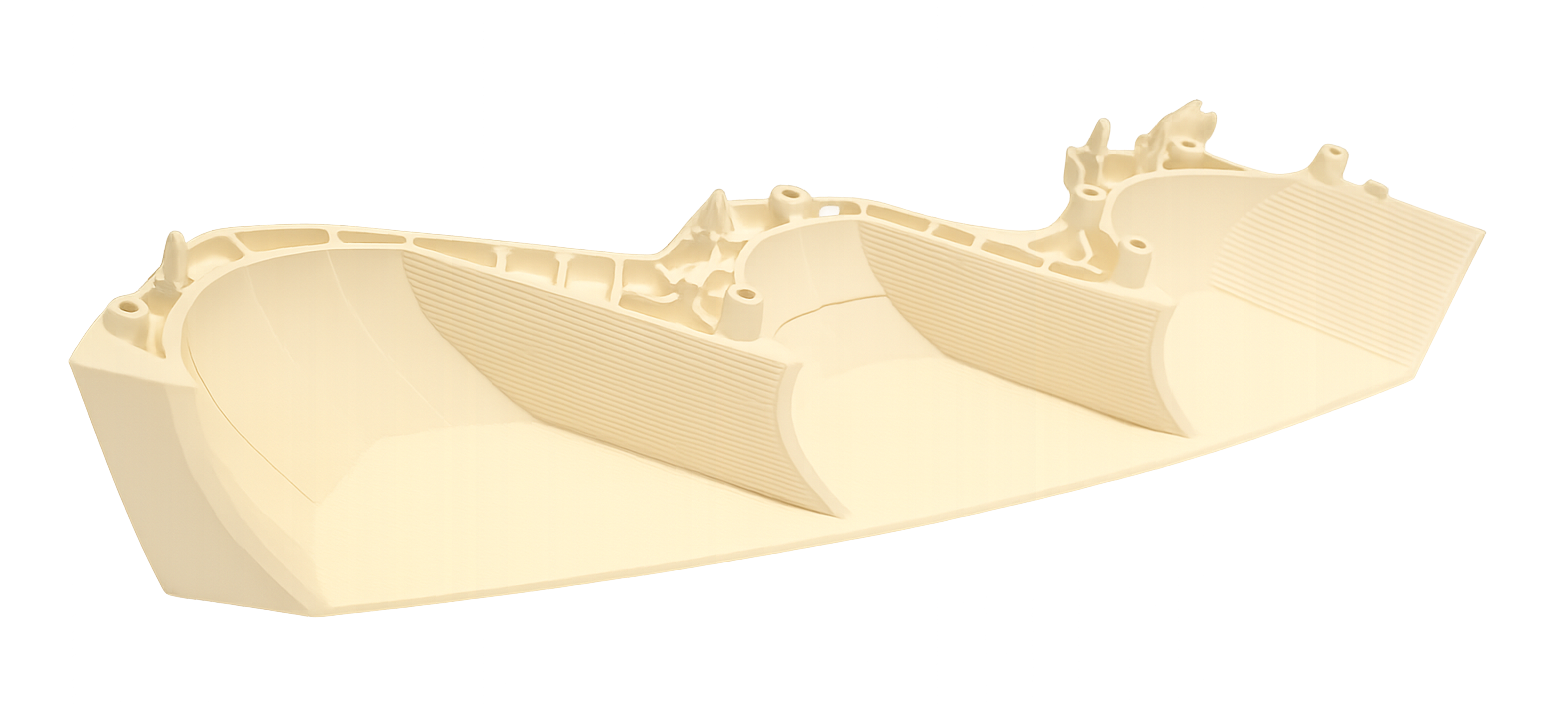

- headlamp carriers,

- components for the automotive industry and electrical devices,

- visually demanding safety components.

Each one demonstrates what BMC can achieve: high mechanical strength, precise tolerances, and premium surface quality.

We are especially proud of our contributions to the automotive industry, where reliability and precision are indispensable — and where Domel’s reputation has been built over decades.

A Place for Young Engineers

Working with BMC combines engineering, innovation, and creativity.

When we introduce young engineers to the field, we tell them:

“Here, you see your ideas come to life — from a model on the screen to a product in your hands. The work is diverse, demanding, and full of challenges that push you to grow.”

Every new project brings opportunities to improve processes, introduce new approaches, and upgrade tools. It is a discipline where every detail matters.

Conclusion

Today, Domel offers a complete solution — from concept to serial production.

With development, tooling, simulation, and manufacturing all integrated, we have become a leader in BMC technology and a trusted partner for customers seeking innovative, reliable, and cost-efficient technical components.

Contact Us

📞 Ana Tehovnik — +386 4 5118 848

Keywords: BMC, duroplastics, housing, carrier frame, toolshop / toolmaking, aluminium alternative, duroplast injection moulding, product development, rich experience, technical expertise

More Domel insights:

This April will mark 80 years since the founding of the "Niko" Metalworkers' Productive Cooperative with Limited Liability, the predecessor of today’s Domel. In this article, we will explore the lessons offered by our rich treasury of experience - from both the recent and more distant past—and how they apply to the challenges of the present day.

Read article

In 2026, Domel proudly marks 80 years of innovation and tradition, which we will celebrate throughout the first half of the year with a rich program of events, open house days, and anniversary exhibitions.

Read article

Thank you for being part of our journey!

Read article

Dear Business Partners, the end of the year is approaching. A time when we traditionally look back and express gratitude for successful cooperation.

Read article

We have concluded an extremely successful week at MEDICA 2025 in Düsseldorf, the world's leading event for medical technology and laboratory equipment. We thank all existing partners, distributors, and visitors who stopped by our Booth B17 in Hall 1.

Read article

In October and November 2025, we had the honor of participating in two significant trade shows in Shanghai: Interclean and the China International Import Expo. These events presented an exceptional opportunity to showcase our innovative solutions and strengthen connections with our partners and the broader industry.

Read article