We work hand in hand with our clients to develop and evolve products over time

Research, develop and grow with us

Domel’s Tools for BMC Thermoset Molding

In the modern thermoset (BMC) injection molding industry, the quality of the tool directly influences the reliability, precision, and cost-efficiency of the final product. Domel has established itself as one of the leading European and global manufacturers of BMC injection molds, with a strong focus on technical excellence, innovation, and comprehensive customer support.

Technological complexity as standard

Manufacturing molds for BMC injection molding presents a significant technical challenge. BMC materials do not shrink and behave similarly to fluids during injection, requiring extremely tight sealing surfaces. All other cavity surfaces must be polished to a high gloss. At Domel’s toolmaking department, we manufacture molds with cavity inserts up to dimensions of 800 × 700 × 400 mm, and sealing surfaces with a precision of 10 µm. Such precision is crucial for maintaining a stable molding process and ensuring the highest product quality.

Reflective surfaces used for optical components are fully produced using CNC milling and require surface roughness of Ra = 0.12 µm, necessitating top-tier machining equipment and full technological mastery of the machining process.

Tool for BMC injection molding prepared for use on a horizontal injection molding machine (photo: Anita Habjan)

In-House Tool development

Domel’s tool development is entirely based on in-house expertise, with all key development stages carried out internally — from filling and thermal simulations to process optimization and final validation. The tool development and design department consist of ten highly skilled engineers, while the entire tool shop includes 75 specialists, ensuring fast information flow, high flexibility, and exceptional manufacturing quality.

Through continuous investment in technological capacity and digitalization, we have automated critical processes, including sinker EDM, HSC milling of graphite electrodes and hardened workpieces, coordinate measuring, and washing — all integrated within one automated cell.

Where are our Tools used?

Our BMC tools are used for injection molding of complex technical and optical components such as:

- Motor housings for vacuum cleaners,

- Motor holders and fully overmolded motors for washing machines,

- Reflectors for the automotive industry (fog lamps, main headlights, headlight brackets),

- Pumps for battery cooling in electric vehicles,

- Airflow regulator housings for automotive applications.

We are capable of developing and manufacturing molds for extremely complex products where precise shaping, resistance to high temperatures, and long-term mechanical durability are critical.

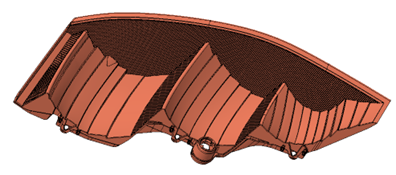

3D model of a headlamp bracket casting

Why choose Domel?

Domel is not merely a tool supplier — we are a strategic partner. We provide expert support from the early design phase, collaborating with customers to assess product feasibility and optimize it according to functional, manufacturing, and cost requirements. Our strength lies in our ability to foresee potential molding issues in advance, enabling us to produce robust and long-term reliable tools.

Additionally, we master even the most demanding technologies, including the insertion of metal inserts and overmolding processes, further expanding the application range of our solutions.

Tool for BMC injection molding prepared for use on a horizontal injection molding machine (photo: Anita Habjan)

Technology behind the process

For CNC program creation, we use the advanced HYPERMILL software, which enables optimized surface machining, shorter production times, and higher machining quality — all essential when producing high-performance optical and technical components.

Conclusion

Domel’s BMC tools represent a premium solution for companies seeking top-tier quality, reliability, and comprehensive technical support. Our dedication to precision, technological excellence, and a partnership-based approach makes us one of the leading players in Europe and globally.

If you want the best possible solution for your projects, Domel is your first choice.

Contact us:

Marko Čenčič

Sales Program Manager

T: +386 4 5118 841

M: +386 41 271 809

E: marko.cencic@domel.com

Keywords: BMC injection molds, BMC tooling, mold manufacturing, product development, BMC product optimization

More Domel insights:

This April will mark 80 years since the founding of the "Niko" Metalworkers' Productive Cooperative with Limited Liability, the predecessor of today’s Domel. In this article, we will explore the lessons offered by our rich treasury of experience - from both the recent and more distant past—and how they apply to the challenges of the present day.

Read article

In 2026, Domel proudly marks 80 years of innovation and tradition, which we will celebrate throughout the first half of the year with a rich program of events, open house days, and anniversary exhibitions.

Read article

Thank you for being part of our journey!

Read article

Dear Business Partners, the end of the year is approaching. A time when we traditionally look back and express gratitude for successful cooperation.

Read article