We work hand in hand with our clients to develop and evolve products over time

Research, develop and grow with us

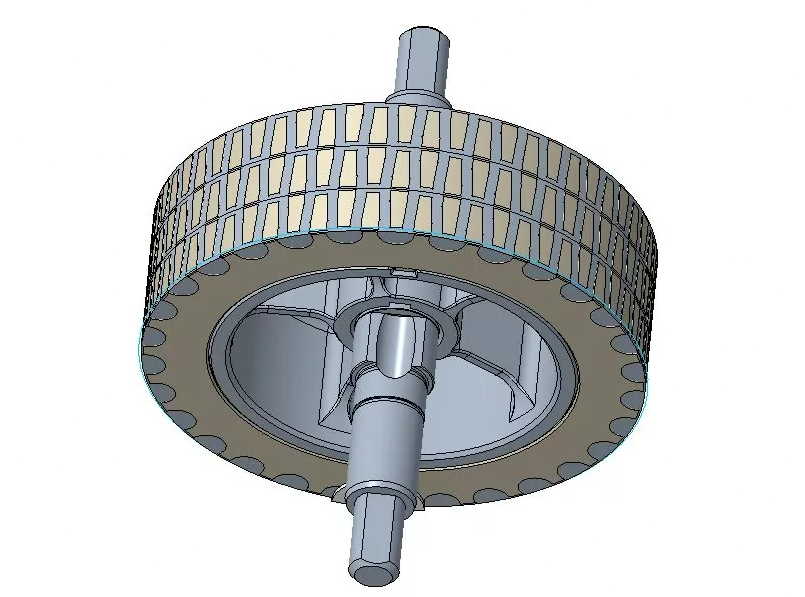

Innovative motor for DREEM e-scooter

Together with Elaphe, Domel developed the TFM (transversal flux) motor for electric kick scooters. The objective of the project was to develop the lightest and most efficient motor.

The motor is developed under the DREEM (Designing useR centric E-kickscooters & business models for Enhancing interModality) project aimed at developing, producing and measuring a safe and modular 3-wheel electric kick scooter for urban and suburban mobility. The project involves 10 partners from six European countries: Italy, Germany, Sweden, Belgium, France and Slovenia. We received European funds for motor development.

“This project has received funding from the European Union's Horizon 2020 research and innovation programme under grant agreement No 101007085.”

Additional information about the kick scooter and the project is available on the website https://dreemscooter.eu/ where you can see the conceptual design of the final product and all associated equipment.

Domel’s innovative motor, which is attached to the front wheel of the kick scooter, replacing the rim, has met all expectations. The three-phase motor with 350 W is 800 g lighter than the comparable BLDC motor, and is among the lightest motors in this power range in the world. It is thermally stable up to 10 Nm of torque, and develops a speed of 520 rpm. Currently, the project is in the phase of the first working prototype. The motor can also be used to drive an e-scooter or e-bike.

The results of measurements are extremely positive and have confirmed the theoretical analysis and FEM (finite element method) calculations. During the project, we were facing numerous challenges which we promptly addressed. The biggest challenge was to produce a stator from sintered material, which is a completely innovative part of the electric motor. The rotor consists of skewed rare-earth magnets.

The project includes a team with a background in development, technology, the prototype workshop, tool shop and measuring station. By the end of the year, we need to produce 40 motors that will be installed in scooters. The scooters will be intended for mobility research conducted in various pilot environments. The urban pilot project will be carried out on the streets of Torino, another pilot project will take place in an industrial plant in Belgium, and the third at the University of Gothenburg. The project will last 2 years.

We offer innovative development solutions tailored to your preferences.

Send InquiryMore Domel insights:

For more than 65 years, Domel has been a global leader in the development of high-performance vacuum motors. Through engineering excellence, innovation, and reliability, we support leading manufacturers of cleaning equipment worldwide. Domel in brief Domel vacuum motors are recognized for their efficiency, durability, and advanced design: Ultra-low vibration levels and quiet operation Best-in-class aerodynamic efficiency (> 55%) 10–30% lower material usage with equal performance Highly automated production with 100% final inspection These strengths make Domel a trusted long-term partner for demanding cleaning applications. Innovation for Modern Cleaning Needs As wet & dry vacuum applications continue to grow, Domel develops advanced EC (brushless) motor solutions for residential, commercial, and industrial environments—combining high efficiency, long lifetime, and robust design. With solutions covering a voltage range from 18 to 230 V, Domel enables both battery-powered and mains-powered applications, offering maximum flexibility for modern cleaning equipment design. Proven and Future-Ready Solutions Domel’s portfolio combines proven reliability with next-generation innovation: 467 – A global standard for durability in wet & dry applications NEW! 457 and 759 – New-generation solutions designed for improved efficiency, sustainability, and future regulations New vacuum motor 457 New vacuum motor 759 Ready for the Future of Cleaning By combining decades of experience with continuous innovation, Domel continues to shape the future of vacuum motor technology and high-performance suction solutions.

Read article

In recent days, Dubai has been the center of global healthcare innovation.

Read article

This April will mark 80 years since the founding of the "Niko" Metalworkers' Productive Cooperative with Limited Liability, the predecessor of today’s Domel. In this article, we will explore the lessons offered by our rich treasury of experience - from both the recent and more distant past—and how they apply to the challenges of the present day.

Read article

In 2026, Domel proudly marks 80 years of innovation and tradition, which we will celebrate throughout the first half of the year with a rich program of events, open house days, and anniversary exhibitions.

Read article